AI Question:

How would you design a device to heat water for steam turbines using hydrogen and oxygen combustion??

AI Answer:

To design a device for heating water using hydrogen and oxygen combustion to generate steam for steam turbines, you would need to create a system that safely and efficiently combines hydrogen and oxygen to produce high-temperature steam. Here's a general outline of the design considerations for such a device:

1. Safety Measures:

• Implement proper safety features to prevent accidental ignition or explosion.

• Install sensors to monitor gas leaks, temperature, and pressure levels.

• Include automatic shut-off mechanisms in case of abnormal conditions.

2. Hydrogen and Oxygen Supply:

• Establish a reliable source of pure hydrogen and oxygen gases.

• Implement storage and handling systems that meet safety standards.

• Ensure proper ventilation and gas distribution throughout the system.

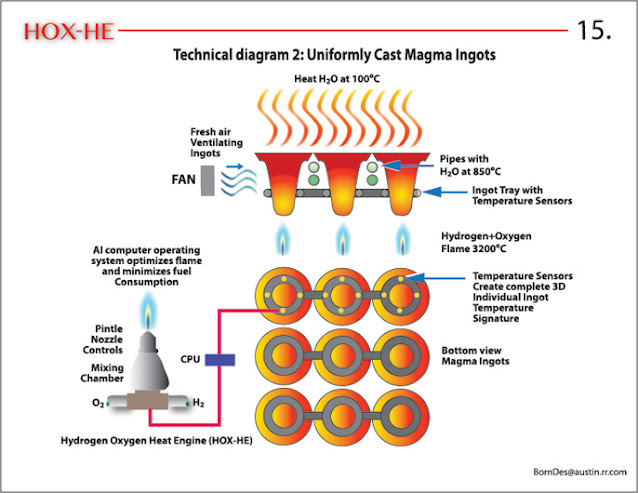

3. Combustion Chamber:

• Design a combustion chamber where hydrogen and oxygen can mix and burn.

• Use appropriate materials resistant to high temperatures and combustion products.

• Incorporate a high-energy ignition system, such as an electric spark or a pilot flame, to initiate the combustion process.

4. Water Heating System:

• Integrate a heat exchanger to transfer the heat generated from the combustion process to the water.

• Optimize the heat transfer surface area to maximize efficiency.

• Implement a water circulation system to maintain a constant flow through the heat exchanger.

5. Steam Generation:

• Use the heated water from the heat exchanger to generate high-pressure steam.

• Include a pressure vessel to store the steam at the desired pressure.

• Install safety valves to release excess pressure and prevent equipment damage.

6. Steam Turbine Connection:

• Connect the steam outlet of the pressure vessel to the steam turbine.

• Ensure proper alignment and sealing to prevent steam leaks.

• Integrate control systems to regulate steam flow and pressure based on the turbine requirements.

7. Waste Gas Treatment:

• Incorporate a system to treat and remove any harmful combustion byproducts.

• Consider using catalytic converters or filters to reduce emissions.

8. Monitoring and Control:

• Implement sensors and control mechanisms to monitor and regulate temperature, pressure, and flow rates.

• Use a control system to automate operations and maintain optimal performance.

• Include safety interlocks to shut down the system in case of critical faults or abnormal conditions.

HOX-HE as part of a Zero Emissions Electrical Production Ecosystem

It's important to note that designing a practical and efficient system for hydrogen and oxygen combustion requires expertise in combustion engineering, materials science, and safety considerations. Working with professionals and consulting relevant safety codes and regulations is essential to ensure the safe and effective operation of the device.