The Missing Key to Utilizing Hydrogen as a fuel to generate Electricity?

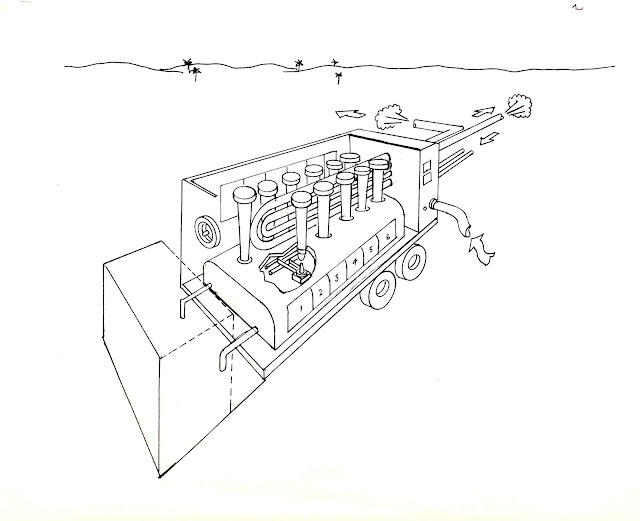

The Retrofittable HOX-He Mobile Unit

Hydrogen + Oxygen fueled Heat Engine

Hydrogen combustion in pure Oxygen produces only recoverable water, H2O.

NO CO2 or HARMFUL POLLUTING nitrogen oxides. NOx.

Based on an a Scientifically Proven and Universal Paradigm

2H2O(l)→ 2H2(g) + O2(g) → 2H2O(l)

Chemical formula for optimum combustion

The HOX-He replaces Fossil Fuels for heating steam to generate electricity, high temperature industries and for use with High Temperature Electrolysis.

Features:

- Uses heated, red hot lava ingots to transfer hydrogen-oxygen combustion‘s high temperature, 3200°C flame into long-term radiant heating.

- New, clean heat source that easily retrofits into all existing steam turbine electrical generators.

- Uses Hydrogen on Demand, produced on-site by both ambient Alkaline and High Temperature Electrolysis,.

- Both Heating Unit and Command Module are totally mobile, transportable and retrofittable.

- Exterior-outdoors usage.

- Quick setup.

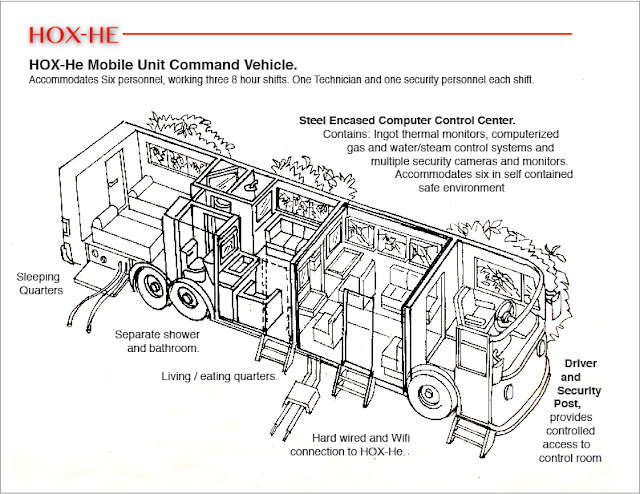

- Self-Contained 24/7 command module.

- Produces steam for both required high temperatures applications, Steam turbines and High Temperature Electrolyzers.

- Stationary application and enclosed chamber recovers water byproduct from hydrogen-Oxygen combustion.

Advantages:

- Glowing lava ingots leverage hydrogen’s high, 3200°C heat by capturing, storing and radiating from a relatively small flame for use over a prolonged periods of time.

- Provides totally green heat source, to 80% of existing electrical generation, replacing fossil fuels.

- On-Site Hydrogen Production eliminates difficulty in storage and transportation of hydrogen.

- Can be easily moved to any thermal steam turbine electrical plant.

- Exterior location eliminates risk of gas buildup.

- Connects directly to steam turbine and High Temperature Electrolyzer.

- Command Module accommodates team of six, 24/7, three shifts of two, technician and security personnel.

- Can heat both existing steam turbines and emerging Hydrogen Fuel Cell technologies.

- Recovers virtually all the water used to make hydrogen in the original Electrolysis process.

Benefits:

- Very efficient, uses small quantities of hydrogen and oxygen gas to keep lava ingots glowing red hot for prolonged periods, enough to heat steam to required high temperatures.

- Works within existing electrical infrastructure and stakeholders while facilitating future hydrogen fuel cell technologies.

- On-site Hydrogen Production resolves need for developing extensive new hydrogen pipeline and storage infrastructure.

- Easily retrofittable into all steam turbine electrical plants and existing electrical grids.

- Exterior location practically eliminates risk of hydrogen explosion.

- Can be used temporarily or permanently.

- 24/7 Supervised operation.

- Paves way for all Hydrogen Fuel Cell future.

- Totally replaces use of fossil fuels and nuclear power.

- Recovers and recycles substantially all the clean water from combustion process for reuse in the Electrolysis Process.

An excellent video guide to the benefits of new High Temperature Electrolyzers (HTE).

Hydrogen from any Biomass.

Microbial Electrolysis Cell (MEC) and Microbial Electrolytic Carbon Capture (MECC) are already producing 2% of the world's industrial Hydrogen from Human Wastewater.

Both MEC and MECC achieve an efficiency of NET POSITIVE Energy Production of 144%. Remarkably, MECC is also a process that has the potential to substantially contribute to the furthering of sustainable energy practices.

MECC results in an actual NET NEGATIVE Carbon Emission from wastewater treatment by removal of carbon dioxide (CO2) emitted during the treatment process in the form of calcite (CaCO3), a widely used industrial material and production of profitable Hydrogen gas.

Undoubtedly Hydrogen from Waste Water is the real goal.

However, while waste water contains toxic pathogens, Fermenting Sargasso contains the same microbes as the Human Intestines and foods like Kimchi. Sargasso can easily serve as a excellent benign biomass substitute for many coastal Electrical Plant retrofits.

The optimum ratio of gases “Hydrogen to Oxygen” is:

2H2O(l)→ 2H2(g) + O2(g) → 2H2O(l)

Chemical formula for optimum combustion

Also matching the amount of each gas produced through electrolysis of water.

It is possible to recover and recycle all the water produced from hydrogen-oxygen combustion in an appropriate designed closed vessel.

View actual lecture hall demonstration.

Hydrogen from Seaweed.

Could Puerto Rico produce all it's electrical needs from Sargasso Seaweed?